April 25, 2019

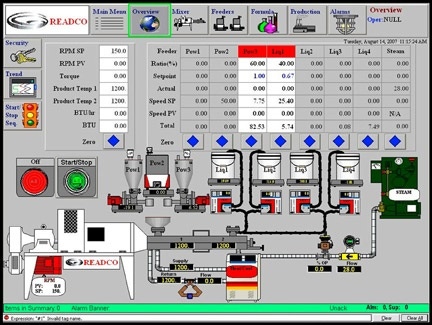

The Readco Process Control System (RCS) integrates mixing, heating, cooling, and feeding into a single, touch-screen HMI.

Offered as an option on the company's continuous processors, the system eliminates the multiple interfaces needed to control individual machines in a batch process in favor of a single interface offering automated, precise control over every step in the mixing process. Powered by Melfi Technologies, the Allen-Bradley PLC-based controller enables a single operator to setup, monitor, and adjust heating and cooling zone temperatures, material feed rates, throughput rates, shear intensity, and other process variables quickly, easily, and on the fly from one screen. The system may also be accessed remotely via the Web or VPN connection or via redundant monitors installed anywhere in the facility, all protected by multiple layers of security to ensure process integrity.

Storing an extensive recipe database, the proprietary continuous operating system archives pre-programmed product formulations that may be instantly recalled for fast, accurate setup and consistent, repeatable processing year after year. In operation, the system automatically logs data for all process variables for live review, recall, and analysis. The RCS is proven in continuous processing for foods, chemicals, plastics, and other products, and integrates seamlessly with loss-in-weight, screw, belt, and vibratory metering feeders and other equipment from many manufacturers without requiring external controls.

Readco Kurimoto LLC, York, PA 800-395-4959 www.readco.com

For related articles, news, and equipment reviews, visit our Instrumentation & Control Equipment Zone

Click here for Instrumentation & Control Equipment Manufacturers

Get information or register for Powder Show Toronto, June 4-6, 2019

You May Also Like