Carrier Vibrating Equipment offers a new bulk material heat exchanger to easily fit into production lines.

August 28, 2020

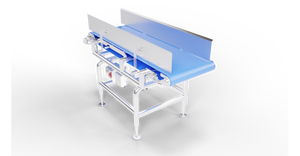

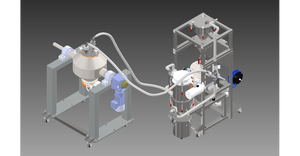

To meet the requirements of customers using other Carrier vibrating equipment for processing material, the company’s R&D team created the new bulk material heat exchanger (BMHX) to easily fit into production lines.

Using a high-efficiency gravity-fed design, the BMHX is capable of heating or cooling material indirectly, removing the risk of contamination and reducing the need for ventilation or dust collectors. The small footprint of the vertical design and low power and ventilation requirements mean the heat exchanger fits easily into existing productions lines, without having to completely rearrange equipment and auxiliaries. The slow plug flow movement of the material reduces product degradation caused by other thermal processing methods and makes this ideal for abrasive materials.

Carrier Vibrating Equipment, Louisville, KY 502-969-3171 www.carriervibrating.com

About the Author(s)

You May Also Like