January 2, 2019

Drying is one of the oldest and most commonly used methods in the processing industry, yet it remains one of the most complex and least understood operations because of the difficulties and deficiencies in mathematical modeling and simulation. In many plants, the dryer is often regarded as “a black box,” where material enters wet and comes out within specifications. It is the responsibility of the operator to be knowledgeable about both the operation of the dryer and processing nuances. This guide will offer a basic reference for the process of maintaining or operating direct recirculation air dryers, selecting a new dryer for a determined process, or assessing process design and energy efficiency.

Products That Satisfy Basic Needs

Most people don’t consider the drying process when they visit the local supermarket. Yet nearly every product on the shelves passes through the drying step at some point during processing. Consider the ready-to-eat cereal aisle. Every cereal, regardless of shape and brand, is dried before packaging. Granola bars made of cereal, fruit, nuts, or chocolate, have ingredients that were dried and stabilized before mixing. The same is true for pet food, which is cooked, extruded, and dried. On the detergent aisle, powdered detergent is manufactured using the dryer. Paper goods are processed from cellulose fiber which is converted to a sheet and dried.

Why Drying Is Needed

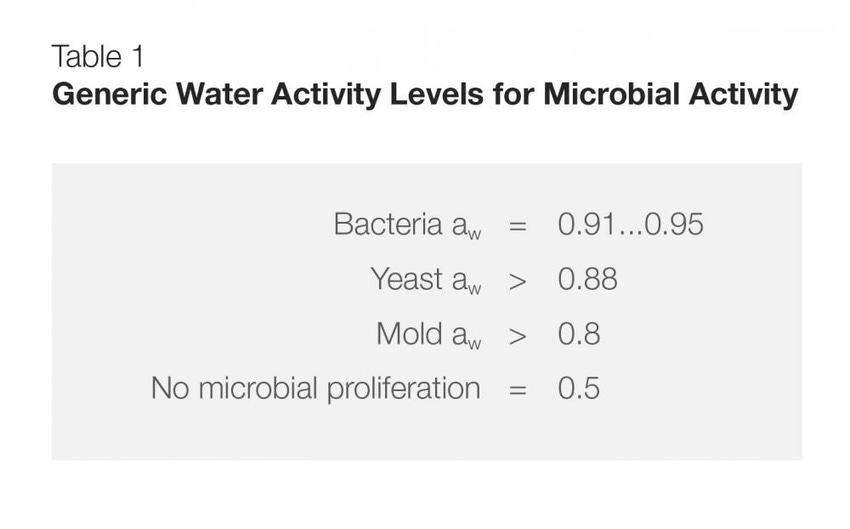

Drying improves product handling and increases shelf life. If material is not dried to the proper level of moisture, food may not be safe for consumption. It could develop mold, an undesirable smell or flavor, or differences in color. In the food, pharmaceutical, and cosmetic industries, the measurement of product moisture in the product considers water content, as well as water activity (aw). The water activity (aw) is the energy state of free water not chemically bound in the substance. If the energy state on free water is high, the water can react with bacteria, yeast, molds, or enzymes. This means that at a certain water activity level, undesirable microbiological growth will occur. See Table 1.

See Table 1 – Generic water activity levels for microbial activity

In general, any food product with a higher moisture content will have a higher water activity. Other reasons to dry could be to achieve a desired chemical change in a chemical compound or to produce a browning or roasting effect. Finally, an additional reason to dry is to reduce weight and volume, which brings an important economic advantage when considering costs for transportation or storage.

The Basic Concepts

Drying: The unit operation that consists of separating a solid from a liquid, by evaporating the liquid into a vapor through the application of heat.

Free moisture: This is the water content which is removable at a given temperature.

Wet Basis – Dry Basis: There are two ways to express how much water there is in a substance. Wet basis is the mass of water in the sample divided by the total mass of the sample:

% Wet basis = (Weight H2O in the sample)/(Weight of solids + Weight of H2O) x 100%

Wet basis is by far the most common way to express the quantity of water in a determined substance.

Dry basis is defined as the quantity of water in a sample divided by the quantity of sample that is not water, or the solids content in the sample:

% Dry basis = (Weight of H2O in the sample)/(Weight of solids in the sample) × 100%

The dry basis and the wet basis are related to each other as:

% D.B. = (%W.B.)/(100-% W.B.)

Notice that the relationship between the wet basis and the dry basis it is not linear.

Drying Media: When moisture evaporates from a solid in form of a vapor, it is necessary for a carrier gas to take that water away from the solid and prevent that water from being deposited again in the solid. This gas is known as the drying media. Most of the time the drying media is hot air or heated air, with products of combustion, but it can be any practical gas, with the only restriction being that the drying media not react with the product.

Airflow Mode: The dryer’s airflow exposes the new product surfaces constantly and consistently, removing excess water vapor from the system. The direction of the drying media relative to the product can be: Co-current (the product and the drying media move in the same direction). In this airflow mode, the air at its maximum temperature will have contact with the wettest product, and the exhaust air will have a temperature close to the product temperature. Counter-current: The product and the drying media move in opposite directions. Here, the driest product will have contact with the air at its maximum temperature, which could be detrimental for some products. Cross flow: The air moves parallel to the product surface, moving across the product without touching it. This flow can be less efficient depending on the product. Through the bed: The air passes through the product from above or below, sometimes in an alternating way, directly exposing the product to the drying media to remove the water vapor.

Air Humidity: Air is a mixture of gases, including oxygen and nitrogen. In the drying process, the water content of the air, or its humidity, is a fundamental variable that affects drying. The most useful way to recognize humidity is to think of the absolute humidity or humidity ratio, which is the mass of water divided by the mass of dry air in the air mixture. Less accurate is the use of the term relative humidity, which expresses in percentage the degree of saturation in the air. As the saturation of the air depends on temperature, and that change is not linear, relative humidity will be highly dependent on temperature. This makes it more confusing to use in heated environments like the dryer. A humidity sensor or hygrometer is used to determine the humidity of an air stream. If a more elaborate sensor is not available, humidity can be determined by measuring the dry bulb and wet bulb temperature on the air. Dry bulb can be determined as any temperature and wet temperature can be determined by covering the thermocouple with a wet sock.

Heat Source: Energy can be supplied to the dryer using gas burners, steam or hot oil coils, electrical heaters, or even a transparent screen that receives sunlight.

Dry Bulb Temperature: Temperature is a measure of the heat of a system, proportional to the kinetic energy of the system. Temperature is measured with a thermometer or a thermocouple.

Wet Bulb Temperature: This is the temperature indicated by a thermometer, covered by a thin film of water. More accurately defined by thermodynamics, it is the temperature reached by moist air and water if the air is adiabatically saturated by the evaporated water. Wet bulb temperature can be determined using two simple thermocouples, one covered with a wet sock, preferable made of cotton.

Retention Time: This is the amount of time that the product will spend in the dryer. General speaking, it is the time required to dry a determined substance, under very specific conditions, dependent on temperature, product, and dryer.

Diffusion: Diffusion is the movement of molecules from a zone with high concentration to a zone of less concentration. Specifically applied in the case of drying, this is where water molecules on a solid move from a wet zone to a zone relatively more dried.

The Drying Curve

When engineers refer to the design of a drying process or drying equipment, there is nothing more important or more challenging to obtain than the drying curve, the graphical representation of how a determined product will dry over time, under certain conditions. Following are stages of the drying curve.

Warm-Up Period: When product enters the dryer, it has a lower temperature than the dryer. During this time, the product is heated by the surrounding hot air, and the evaporation rate will remain low. The duration of this period will depend on the temperature difference between the product and the media, and the heating capacity of the material.

Constant Rate Period: Once the product has warmed up and at the maximum temperature, the constant rate period starts. During this period, the rate of evaporation – the quantity of water that is leaving the product at a given time – remains constant. At this time, heat transfer dominates and the evaporation rate is set by the temperature and humidity of the air, along with the air velocity passing through the product.

Critical Moisture Content: This is where the drying curve changes trajectory. The constant rate period ends, and the falling rate period begins.

Falling Rate Period: Once the critical moisture content is reached, the evaporation rate starts to fall. For every unit of time that passes, the amount of evaporation decreases. Temperature is the main variable that affects the drying curve. When the heat temperature is increased, the system heat increases, and the water on the solid increases its energy until the point where water evaporates. The higher the temperature, the faster the process, making the drying curve steeper. Air is another important variable. If air is excessively wet, the product will dry more slowly, and the speed of air will affect the drying time. Each variable and how it is presented to the product, will generate a different drying curve.

One variable often overlooked is the product itself. A larger particle will take more time to dry, as diffusion will take control so that the falling rate period dominates the curve. But if that same particle is cut into smaller pieces, the drying curve will be totally different, with a longer constant rate period and a shorter falling rate period. Surface characteristics will also impact the drying curve. For instance, if the product is porous it will dry faster.

(see Drying Curve chart)

Components of the Convection Dryer

Each convection dryer has the following components in common:

Product: The dryer is designed for a specific product. Product needs to be introduced to the drying environment in a continuous way, or by hand in batch mode.

Heat Source: Every dryer has an energy source to dry the product in a reasonable amount of time.

Circulated Air: The simplest but most inefficient way to move air in a dryer is by natural convection. Almost every dryer in the industry moves air with a fan driven by an electric motor.

Wall Barrier: Once air has been heated by the heat source, it is directed to the trough via a fan. It is more efficient and easier to control these phenomena in an enclosure. The enclosure or barrier is the dryer wall. To avoid excessive losses, the wall must be properly insulated.

Exhaust Air: Once water has been evaporated from the product, the water must be removed or it will accumulate in the enclosure until it condensates in the walls or returns to the product. This is the reason to exhaust humid air.

Make-up Air: After removing the wet air from the enclosure, dry air must replace it. If this steady state is not maintained, the dryer will be unbalanced.

Recirculation: (optional) A once-through air system occurs when air passes through the product once and then the air is exhausted. However, this hot exhausted air which is not yet saturated, could be re-used to save energy. Although it requires more controls, a convection dryer with recirculation is, by principle, more efficient than a once-through dryer.

(see Basic Convection Dryer chart)

Basic Convection Dryer - How to Improve Dryer Operations

There is much more to understanding dryer operations. For instance, how can one determine the precise amount of recirculated air needed? How can one be sure excess product is not being lost? To answer these questions and optimize the drying process, precise information is needed from sensors that measure different variables of the dryer. These include air temperature, humidity of the air, product moisture, energy consumption, and product rate. In general, having an advanced control system in place will enable operators to save 10-20% of energy consumption.

Selecting the Right Dryer for the Task

Selecting a dryer is not an easy task because every technical and economic variable plays an important role in the decision. The goal is to obtain a dryer that performs the task and delivers a product fulfilling all the required specifications within a reasonable cost. Following are some considerations.

Batch Versus Continuous

Consider the application. Is it for a pilot plant or a laboratory? Will be used intermittently or for continuous production. For production scale, what are the required characteristics for the up-stream and downstream processes. Answering these questions, while considering the quantity of material that will be dried, can help determine whether a continuous or a batch dryer is needed. It also depends on the product and the amount of moisture that must be removed. As a rule, to dry 50 110 lb/hr, a batch dryer will probably be the right choice. To obtain more than 440 lb/hr, a continuous unit will be more suitable. If the production quantity falls in between, the advantages and disadvantages of both modes should be analyzed in more detail.

Focus on the Product

Recognizing the product and its unique characteristics is most important. This could include: defining the product characteristics; identifying the shape and size (even particle distribution) of the product; understanding the initial moisture content from the up-stream process; and knowing the desired final moisture content, the maximum temperature, and the drying curve or drying characteristics, if available. This also includes the characteristics of wet product (sticky, free flowing, brittle, etc.); the characteristics of dry product (sticky, dusty, free flowing, etc.); and the physical and chemical properties of the product (bulk density, specific heat, chemical reactivity, flammability, etc.).

Capital Costs and Operation Cost

Unfortunately, many buyers focus on the cost of the dryer only, without considering other costs that impact selection. A less efficient drying technology may require a smaller initial investment, but with extra fuel requirements, it may cost the buyer more over time. Another consideration is maintenance costs. A smarter design may cost more but could be easier to maintain than a poorly designed one. Downtime for cleaning is also important. When a unit is easier to clean and designed to handle food processing hygienically, intervals for cleaning the unit will be adequate and any potential risks will be minimized.

Selecting the right dryer and supplier should be carefully considered. Drying involves more than technology. It is an amalgamation dependent on science and precise know-how, from decades of observation.

Aldo De Tuoni, Senior Applications Engineer, Bühler Aeroglide. For more information, visit www.buhlergroup.com.

For related articles, news, and equipment reviews, visit our Drying & Thermal Solids Processing Equipment Zone

Click here for a List of Drying & Thermal Solids Processing Equipment Manufacturers

You May Also Like