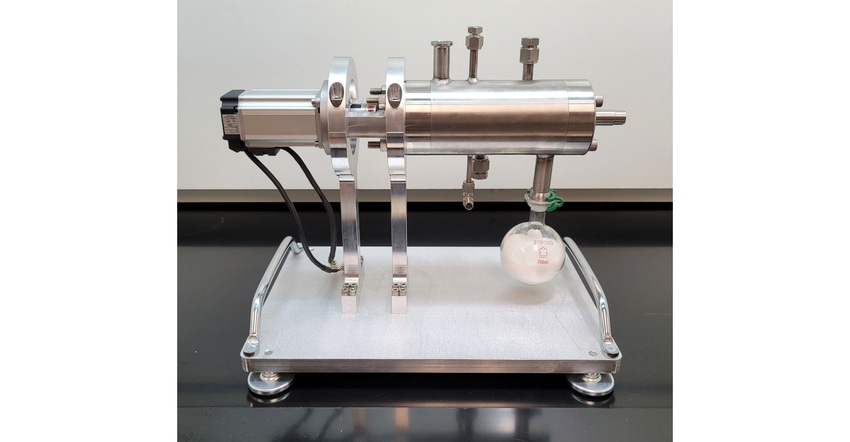

Evaporator/dryer is designed for continuous evaporation and liquid-to-powder drying of heat-sensitive materials.

March 28, 2023

The Rototherm Mini utilizes the same thin-film separation technology as Artisan’s production-scale Rototherm evaporators. It is designed for continuous evaporation and liquid-to-powder drying of heat-sensitive materials.

Horizontal Orientation

Unlike vertical evaporators, the Rototherm Mini has a horizontal orientation that provides researchers complete control over residence time. This allows for liquid-to-powder drying in a single pass and improved product yield.

Enhanced Design

The Rototherm Mini features a high-speed rotor that utilizes centrifugal force to create an agitated thin-film. This design provides improvements over traditional wiped-film evaporators (WFE). It is capable of processing viscous or foaming liquids and slurries. In addition, the stainless steel, fixed-clearance rotor provides easier cleaning.

Scale-Up

The Rototherm Mini provides researchers the ability to develop continuous processes at lab-scale that can be scaled-up for production.

Additional product specifications include:

5-50 ml/min feed rate

Maximum operating temperature 450°F

Operating pressure - full vacuum to 15 psi

316 stainless steel construction

Easy to clean

Artisan Industries Inc., Stoughton, MA 781- 893-6800 www.artisanind.com

About the Author(s)

You May Also Like