Kettering University is bringing Industry 4.0 to engineering and computer science classrooms for a hands-on learning lab.

Patti Engineering Inc. a control system integrator based in Auburn Hills, MI, is one company changing the classroom at Kettering University (Flint, MI). Patti is in partnership with BorgWarner to develop an Industry 4.0-enabled collaborative robotic cell for student learning.

The lab is designed to help teach engineering and computer science students about real-world situations with manufacturing automation technologies they may experience during their co-ops and future careers.

Kettering, a small, private university, is Patti Engineering Inc. CEO Sam Hoff's alma mater. Hoff, who graduated with an electrical engineering degree in 1990, has supported the University in many ways over the years. This, coupled with Patti Engineering's expansive knowledge base in the industrial controls, robotics, and practical application of Industry 4.0 digitalization technologies, makes it a perfect partnership.

Scott Grassman, dean of the College of Engineering at Kettering University agrees.

“We are thrilled to incorporate real-world applications into a single robotic cell for our students to learn industrial robotics, control systems, the internet of things, wireless communications, and data analytics," he said.

Industrial manufacturing students, electrical and computer engineering students, and computer science students will work side-by-side on the different learning opportunities that the robotic cell offers.

"We will even integrate our 3D printing course into developing the end-of-arm actuators for the collaborative robot. It’s a comprehensive system designed to be utilized by all of our engineering and computer science programs," Grassman added.

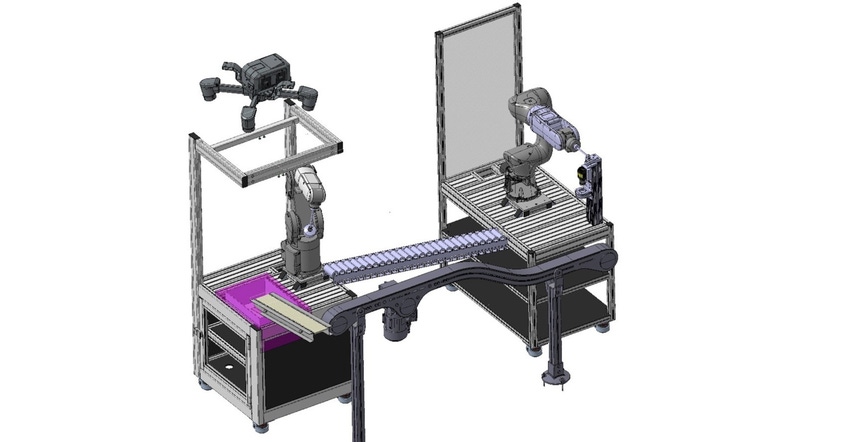

Patti Engineering was involved with the design of the new classroom lab, along with developing the baseline program. The new robotic cell incorporates technology from a couple of the university’s corporate sponsors including Mitsubishi Electric for the PLC, HMI, and collaborative pick-and-place robot; and Keyence for the vision systems and area scanners.

To facilitate learning and experimentation, the robotic cell was designed to enable students to work with and modify the code. At the end of the term, the staff resets the code to the baseline program, giving the same opportunities to the next class.

The future of robotics is a hot topic to many. On one side, there are people who applaud the use, which allows them to work on less menial tasks in a facility. On the other hand, many feel that robots will take jobs of those who need work.

"The need for tech is always going to be there. I see it all the time. Even with robotics, we will need robotics techs," explained Hoff.

Hoff sees a huge gain in efficiency and profitability, with employees working along with robots.

Patti Engineering also has done work in partnership with Purdue University (West Lafayette, IN) and is in talks with Michigan Technological University (Houghton, MI), which already has a robotics lab.

Kettering University works as a five-year co-op model, with work and school, which lasts five years. Students need to write a thesis for graduation. Currently, the university has separate labs to correspond with different courses. The new lab will be integrated into existing courses and will be available for use in future courses.

The university's new lab is scheduled to open in summer 2023.

About the Author(s)

You May Also Like