January 16, 2018

Control Concepts’ AirSweep material activation system delivers on-demand product flow, eliminates material buildup, and enhances batch uniformity.

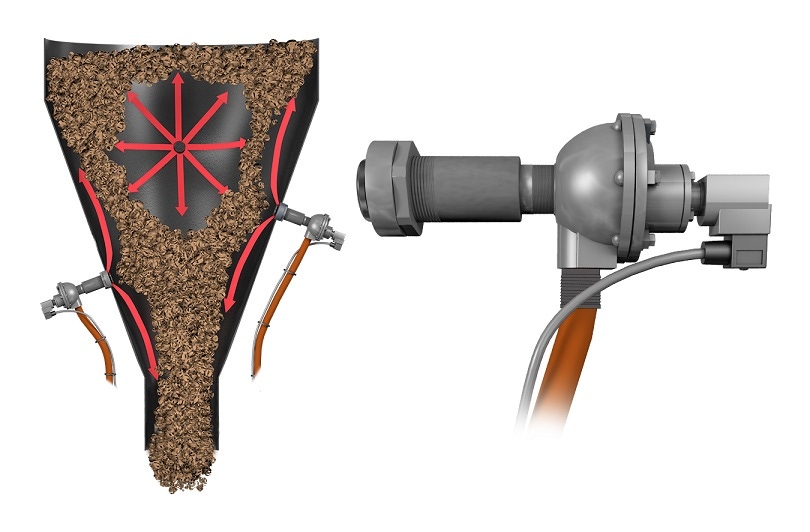

Each AirSweep nozzle directs a high-pressure, high-volume 360° burst of compressed air or gas along the inside walls of process equipment or vessels, breaking friction to lift and sweep stalled material back into the flow stream. The patented nozzle design ensures an immediate reseal after each pulse to eliminate material feedback. Sweeping up to an 8-ft-diam of wall surface with each pulse, the system is also effective for flushing material from mixers, blenders, cyclones, and spray dryers.

The typical AirSweep system uses only 10-20 cfm of existing plant compressed air. Installed and serviced entirely from the vessel’s exterior, AirSweep nozzles easily retrofit to almost any vessel, cone, chute, or wall made from metal, concrete, fiberglass, or wood. Threaded, non-threaded, and tri-clamp mounting styles available to fit a wide range of applications, including those requiring quick disconnect/reconnect for portability or cleaning.

Other models include a USDA-accepted design for sanitary processes and a Straight Shooter option designed to direct a focused column of air to reach and activate material not accessible by the standard AirSweep pulse pattern. AirSweeps are precision-machined in the U.S. from high-grade alloys for long service life.

Control Concepts Inc., Putnam, CT 860-928-6551 www.airsweepsystems.com

You May Also Like