Mixers & Blenders

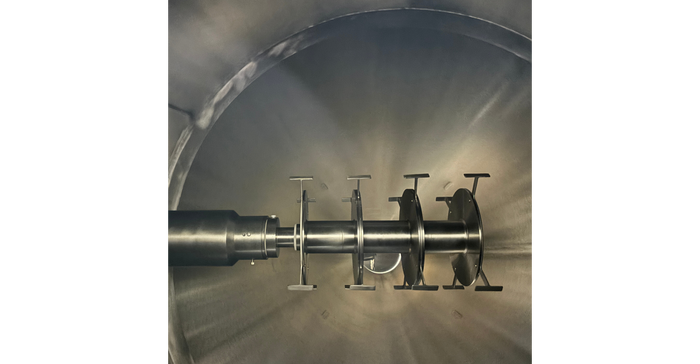

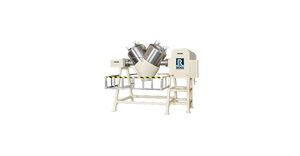

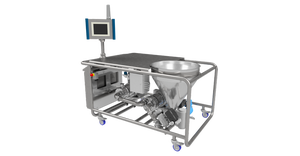

Mars Mineral Delivers Advanced Pin Mixer to LD Carbon's South Korean Operations

Mixers & Blenders

Mars Mineral Delivers Advanced Pin Mixer to LD CarbonMars Mineral Delivers Advanced Pin Mixer to LD Carbon

LD Carbon will open its new South Korea facility in Q2.

Sign up for the Powder & Bulk Solids Weekly newsletter.