Equipment

More Topics

- Bags & Bag Handling

- Drying

- Dust Collection

- Explosion Protection & Safety

- Industrial Feeders

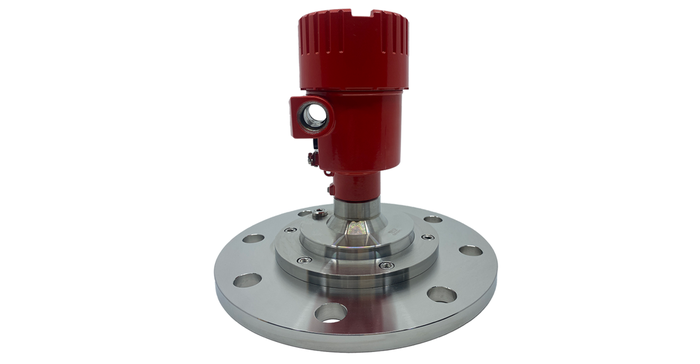

- Instrumentation & Control

- Material Handling & Transport

- Mechanical Conveying

- Mixers & Blenders

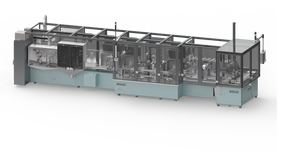

- Packaging Systems

- Particle Enlargers & Formers

- Pneumatic Conveying

- Screening & Separation

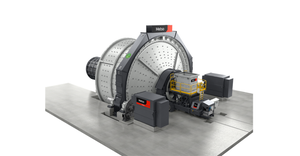

- Size Reduction

- Storage

- Valves, Gates, & Airlocks

- Weighing Systems & Scales

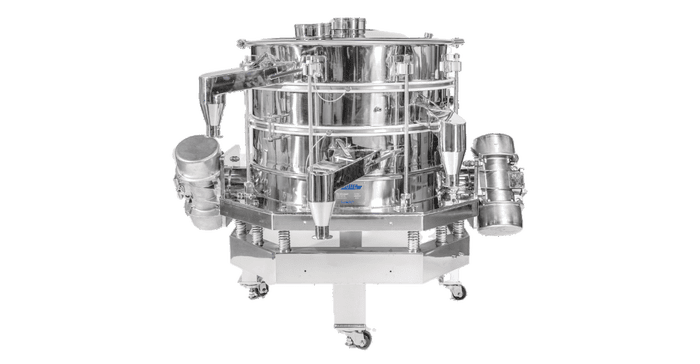

WEDA supplies feeding system to EcoGreen

Industrial Feeders

WEDA Supplies Feeding System to Insect ProducerWEDA Supplies Feeding System to Insect Producer

Portuguese breeder EntoGreen produces animal protein and organic fertilizer from byproducts by ag and food industry.

Sign up for the Powder & Bulk Solids Weekly newsletter.