Equipment

More Topics

- Bags & Bag Handling

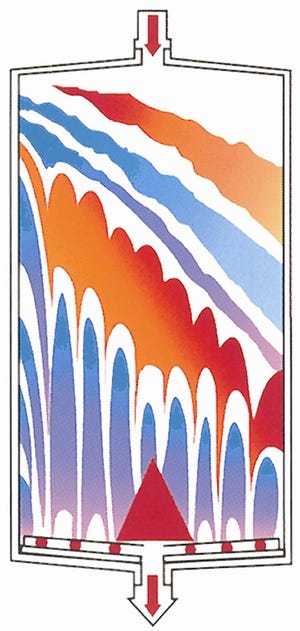

- Drying

- Dust Collection

- Explosion Protection & Safety

- Industrial Feeders

- Instrumentation & Control

- Material Handling & Transport

- Mechanical Conveying

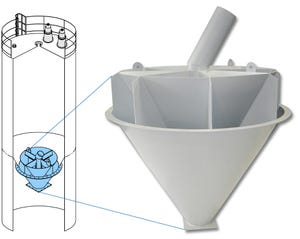

- Mixers & Blenders

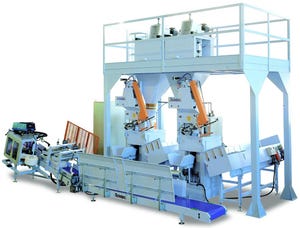

- Packaging Systems

- Particle Enlargers & Formers

- Pneumatic Conveying

- Screening & Separation

- Size Reduction

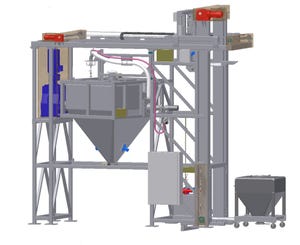

- Storage

- Valves, Gates, & Airlocks

- Weighing Systems & Scales

Sign up for the Powder & Bulk Solids Weekly newsletter.