Equipment

More Topics

- Bags & Bag Handling

- Drying

- Dust Collection

- Explosion Protection & Safety

- Industrial Feeders

- Instrumentation & Control

- Material Handling & Transport

- Mechanical Conveying

- Mixers & Blenders

- Packaging Systems

- Particle Enlargers & Formers

- Pneumatic Conveying

- Screening & Separation

- Size Reduction

- Storage

- Valves, Gates, & Airlocks

- Weighing Systems & Scales

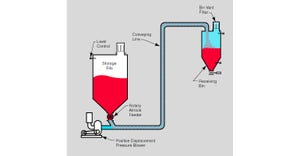

Plant_Expansion_ENSIGN_EQUIPMENT.png

Material Handling & Transport

Ensign Equipment Completes Plant ExpansionEnsign Equipment Completes Plant Expansion

Supplier of material handling equipment and integrated systems for handling dry bulk solids, has completed a 10,000-sq-ft expansion of its assembly plant.

Sign up for the Powder & Bulk Solids Weekly newsletter.