Equipment

More Topics

- Bags & Bag Handling

- Drying

- Dust Collection

- Explosion Protection & Safety

- Industrial Feeders

- Instrumentation & Control

- Material Handling & Transport

- Mechanical Conveying

- Mixers & Blenders

- Packaging Systems

- Particle Enlargers & Formers

- Pneumatic Conveying

- Screening & Separation

- Size Reduction

- Storage

- Valves, Gates, & Airlocks

- Weighing Systems & Scales

Employee with dust silo

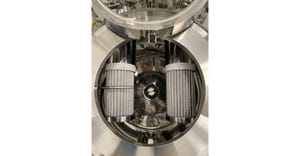

Dust Collection

Don't Waste Your (Up)Time: Invest in Dust Collection System MaintenanceDon't Waste Your (Up)Time: Invest in Dust Collection System Maintenance

Routine dust collection system maintenance can make all the difference to improve uptime, productivity, and safety in your operations.

Sign up for the Powder & Bulk Solids Weekly newsletter.