Equipment

More Topics

- Bags & Bag Handling

- Drying

- Dust Collection

- Explosion Protection & Safety

- Industrial Feeders

- Instrumentation & Control

- Material Handling & Transport

- Mechanical Conveying

- Mixers & Blenders

- Packaging Systems

- Particle Enlargers & Formers

- Pneumatic Conveying

- Screening & Separation

- Size Reduction

- Storage

- Valves, Gates, & Airlocks

- Weighing Systems & Scales

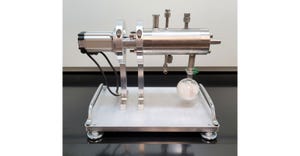

ACS Valves material flow

Valves, Gates, & Airlocks

Why Do Rotary Airlocks Leak, and When is it a Cause for Concern?Why Do Rotary Airlocks Leak, and When is it a Cause for Concern?

A small amount of air leakage is expected in rotary airlock valves, but a larger leak may be cause for concern. Learn how to identify a problematic leak with these tips.

Sign up for the Powder & Bulk Solids Weekly newsletter.