Equipment

More Topics

- Bags & Bag Handling

- Drying

- Dust Collection

- Explosion Protection & Safety

- Industrial Feeders

- Instrumentation & Control

- Material Handling & Transport

- Mechanical Conveying

- Mixers & Blenders

- Packaging Systems

- Particle Enlargers & Formers

- Pneumatic Conveying

- Screening & Separation

- Size Reduction

- Storage

- Valves, Gates, & Airlocks

- Weighing Systems & Scales

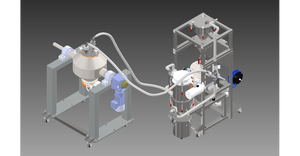

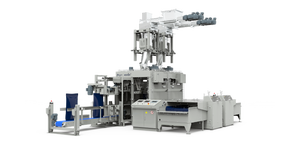

powdered conveying system

Bags & Bag Handling

Optimizing Bulk Bag Filler Offers Significant RewardsOptimizing Bulk Bag Filler Offers Significant Rewards

An expert integrator reveals best practice strategies to increase productivity and profit by upgrading critical bulk bag filling equipment.

Sign up for the Powder & Bulk Solids Weekly newsletter.