Equipment

More Topics

- Bags & Bag Handling

- Drying

- Dust Collection

- Explosion Protection & Safety

- Industrial Feeders

- Instrumentation & Control

- Material Handling & Transport

- Mechanical Conveying

- Mixers & Blenders

- Packaging Systems

- Particle Enlargers & Formers

- Pneumatic Conveying

- Screening & Separation

- Size Reduction

- Storage

- Valves, Gates, & Airlocks

- Weighing Systems & Scales

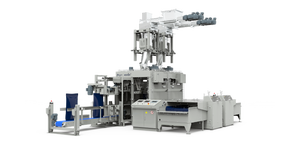

Premier Tech and MG Tech Partner on Packaging Technology

Packaging Systems

Premier Tech and MG Tech Partner on Packaging TechnologyPremier Tech and MG Tech Partner on Packaging Technology

The partnership will meet manufacturers' needs in the nutrition, industrial, fast-moving consumer goods, and parapharmacy industries.

Sign up for the Powder & Bulk Solids Weekly newsletter.