Equipment

More Topics

- Bags & Bag Handling

- Drying

- Dust Collection

- Explosion Protection & Safety

- Industrial Feeders

- Instrumentation & Control

- Material Handling & Transport

- Mechanical Conveying

- Mixers & Blenders

- Packaging Systems

- Particle Enlargers & Formers

- Pneumatic Conveying

- Screening & Separation

- Size Reduction

- Storage

- Valves, Gates, & Airlocks

- Weighing Systems & Scales

Johnson Matthews Chooses Ajax Screw Conveyor for Handling Operations

Mechanical Conveying

Johnson Matthews Chooses Ajax Screw Conveyor for Handling OperationsJohnson Matthews Chooses Ajax Screw Conveyor for Handling Operations

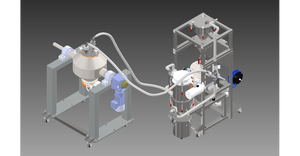

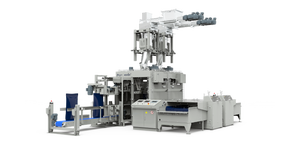

The equipment will enhance the handling of a catalyst material at temperature.

Sign up for the Powder & Bulk Solids Weekly newsletter.